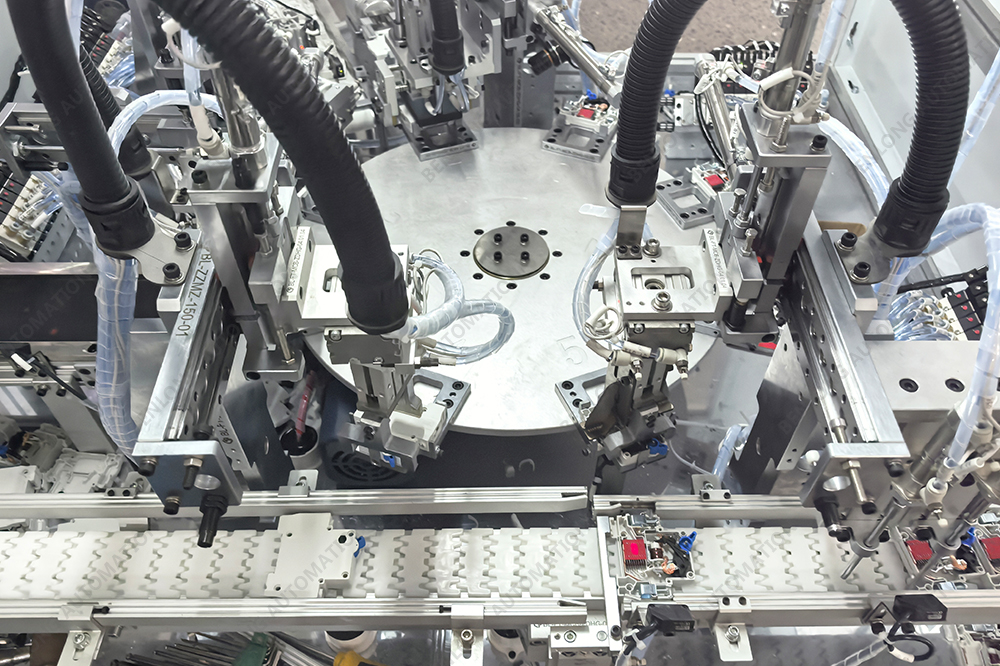

MCB miniature circuit breaker automatic closing machine

See More>>Core Functions

Automatic loading and positioning

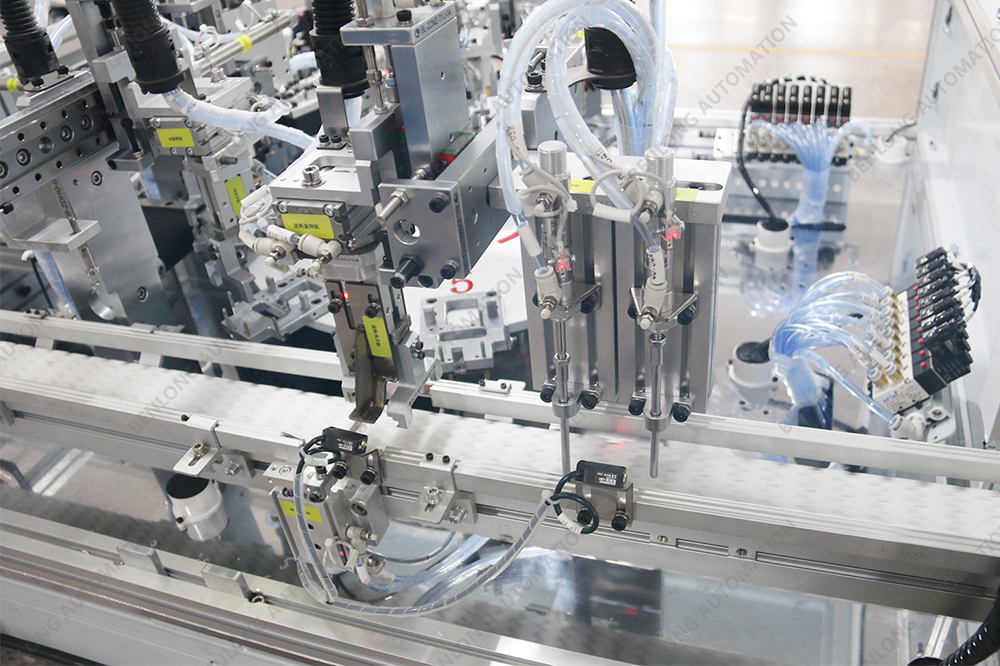

Automatically conveying the top and bottom caps by vibrating plate, conveyor belt or robot to ensure the same direction and position.

The vision system or sensor detects the direction of the cover and corrects the misalignment to ensure accurate alignment before closing the cover.

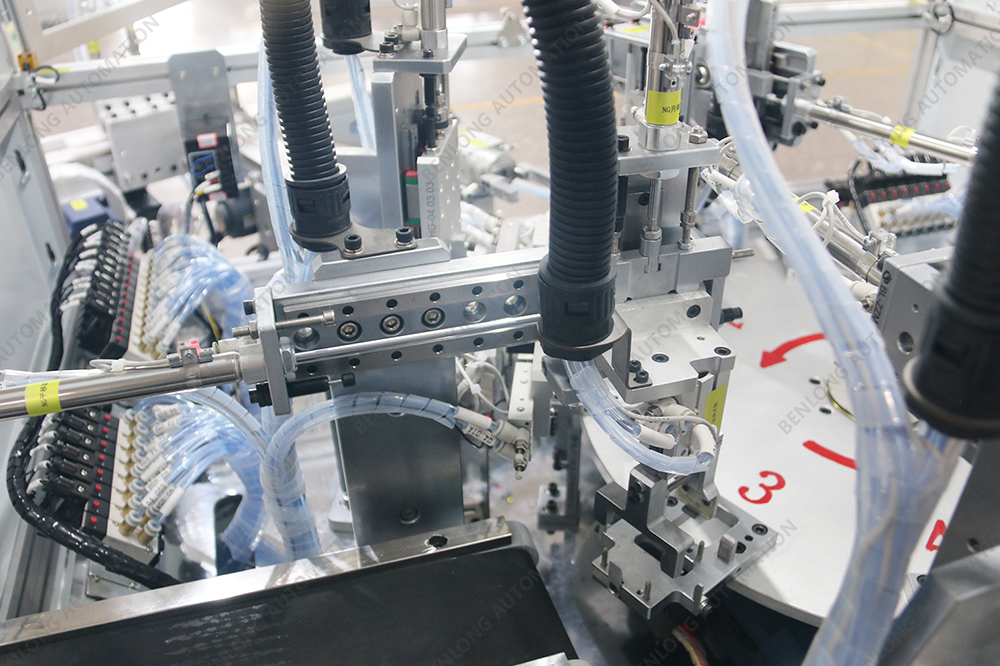

Closing and pressing

Adopts cylinder, servo motor or hydraulic mechanism to apply controllable pressure to press the top cover and bottom cover into place.

The pressure is adjustable to avoid overpressure damage to the MCB shell or internal components.

Quality Inspection

The pressure sensor detects the strength of closing the cover to ensure the tightness of the press-fit.

A vision system checks the appearance (e.g. gaps, misalignments) or functionality (e.g. key flexibility) of the closure.

Sorting of defective products

Automatically rejects products with incomplete closure, cosmetic defects or failed tests.

Data Recording and Traceability

Records parameters such as closing pressure, time, pass rate, etc., and supports production data traceability (optional PLC or MES system docking).

1, equipment input voltage 220V ± 10%, 50Hz; ± 1Hz;

2, equipment compatible with the number of poles: 1P, 2P, 3P, 4P

3, equipment production beat: 1 second / pole, 1.2 seconds / pole, 1.5 seconds / pole, 2 seconds / pole, 3 seconds / pole; five different specifications of equipment.

4, the same shell frame products, different poles can be switched by one key or sweep code switching; different shell frame products need to manually replace the mold or fixture.

5、Defective product detection: CCD vision detection or fiber optic sensor detection is optional.

6, assembled parts feeding method for the vibration plate feeding; noise ≤ 80 dB.

7, equipment fixture can be customized according to the product model.

8、Equipment with fault alarm, pressure monitoring and other alarm display function.

9, Chinese version and English version of the two operating systems.

10、All core parts are imported from Italy, Sweden, Germany, Japan, the United States, Taiwan and other countries and regions.

11, the equipment can be optional “intelligent energy analysis and energy saving management system” and “intelligent equipment service big data cloud platform” and other functions.

12、Independent independent intellectual property rights

MCB automatic assembly Top cover machine