BENLONG AUTOMATION

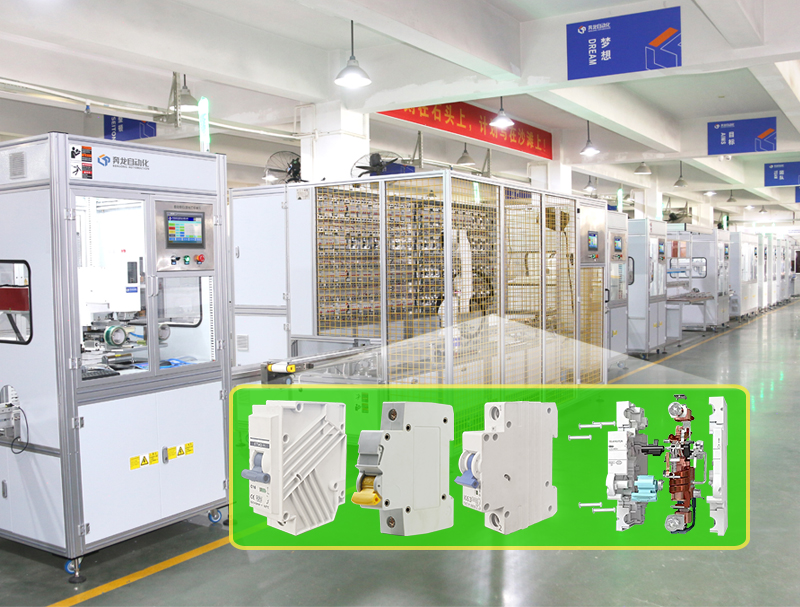

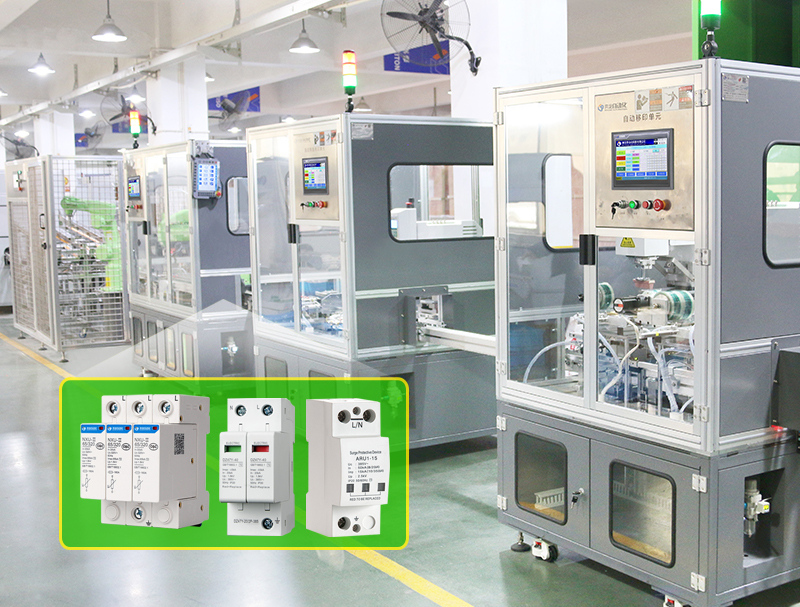

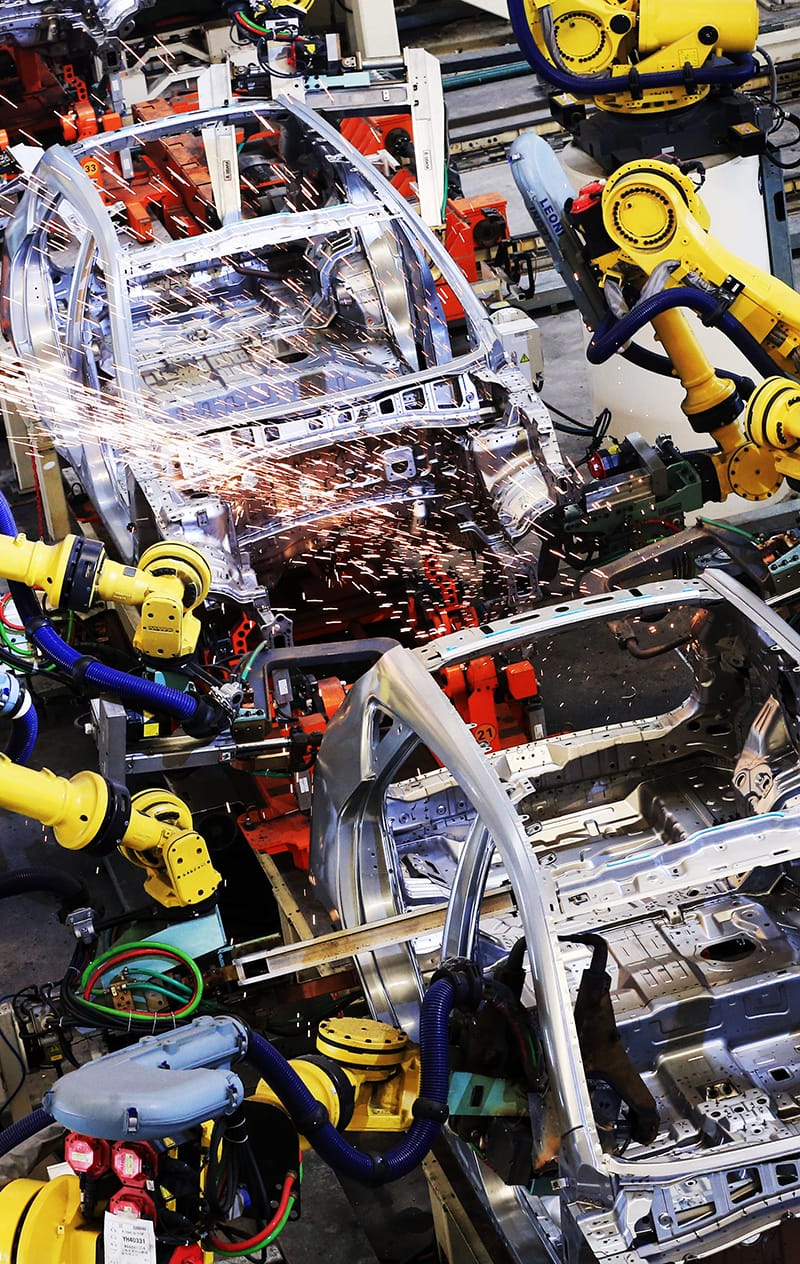

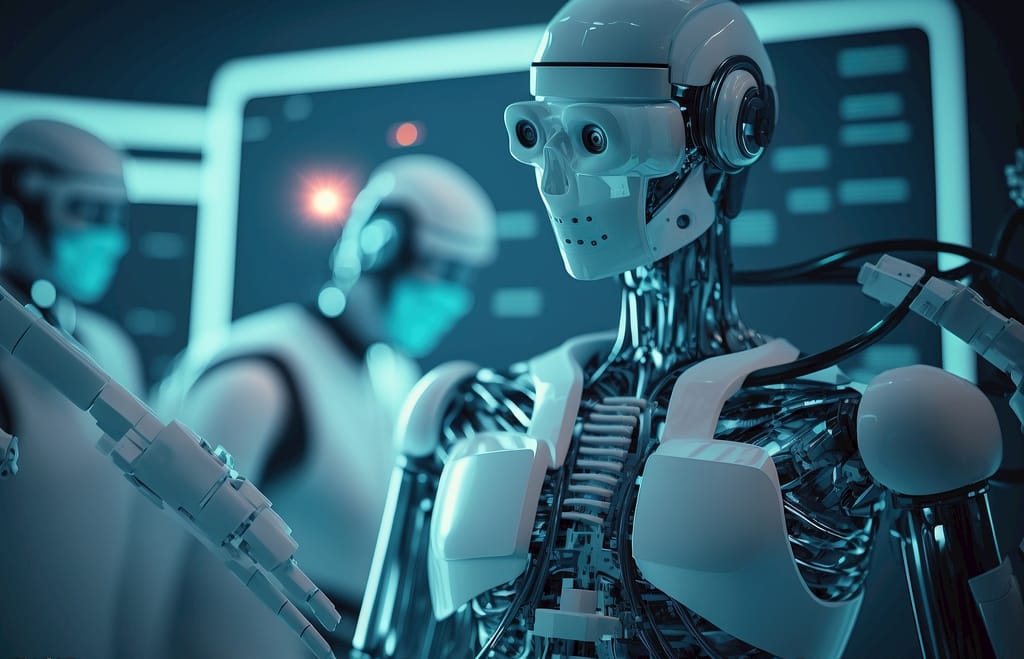

Benlong Automation Technology Co., Ltd. is a national high-tech enterprise with automation system integration technology as its core, focusing on digital intelligent manufacturing equipment. Established in 2008, with a registered capital of 50.88 million yuan, it is located in Wenzhou, one of the “Capital of Electrical Appliances in China”. In 2015, it obtained the “National High tech Enterprise” certificate, owned 146 national patents, and 26 software copyrights, We have successively won honors such as “Zhejiang Province Science and Technology Small and Medium sized Enterprise”, “Yueqing City Science and Technology (Innovation) Enterprise”, “Yueqing City Patent Demonstration Enterprise”, “Contract abiding and Trustworthy Enterprise”, “Zhejiang Province Science and Technology Progress Award”, and AAA level credit enterprise.