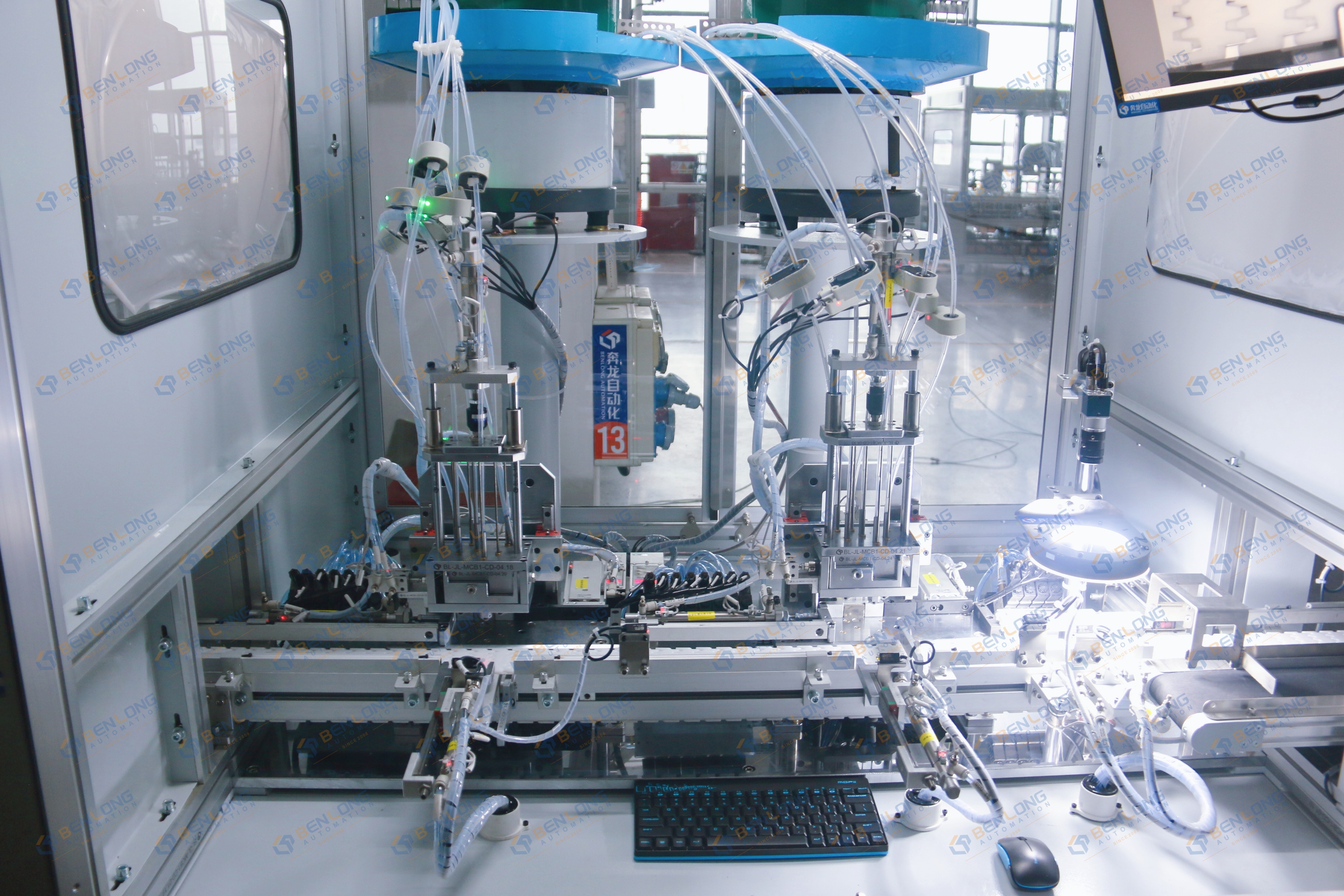

Automatic Pin Insertion Machine

See More>>Process Flow of MCB Automatic Pin Insertion Machine

Ⅰ. Parts Feeding

· MCB Housing: The MCB housings are automatically fed into the machine, typically via a conveyor belt, to the designated insertion station.

· Pins: The pins (or rivets/contacts) are automatically fed from a storage container, such as a vibratory bowl feeder or a linear feeder, which orients and sorts them for consistent delivery.

Ⅱ. Workpiece Positioning and Clamping

· The MCB housing is transferred to the workstation and is accurately positioned and clamped by a precision jig to ensure stability and proper alignment for the pin insertion process.

This step is critical for preventing misalignment.

Ⅲ. Pin Insertion

· The pins are delivered to the insertion head, often via a feed track.

· A pneumatic cylinder or a servo-driven unit pushes the pin from the insertion head and into the pre-drilled hole of the MCB housing.

This action is carefully controlled to ensure the pin is fully seated without damaging the part.

Ⅳ. Pin Forming (If Applicable)

· If the machine is also a riveting machine, a riveting head will then press down on the inserted pin to deform its end, creating a secure mechanical connection. This step ensures the pin is firmly locked in place.

V. Quality Inspection

· Sensors, such as vision systems or displacement detectors, are used to perform a quality check. They verify the presence of the pin, its correct depth, and proper alignment.

· Any defective parts, such as those with missing or misaligned pins, are automatically identified and ejected from the production line.

Ⅵ. Workpiece Transfer

· The completed MCB housing with the inserted pin is released from the jig.

· It is then transferred to the next station for subsequent processes, such as the installation of other components, functional testing, or final assembly.

1, equipment input voltage 220V/380V ± 10%, 50Hz; ± 1Hz;

2, equipment compatible with the number of poles: 1P, 2P, 3P, 4P, 5P

3, equipment production beat: 1 second / pole, 1.2 seconds / pole, 1.5 seconds / pole, 2 seconds / pole, 3 seconds / pole; five different specifications of the device.

4, the same shell frame products, different poles can be switched by one key or sweep code switching; different shell frame products need to manually replace the mold or fixture.

5、Rivet feeding mode is vibrating plate feeding; noise ≤ 80db; rivet quantity and mold can be customized according to product model.

6、The speed and vacuum parameter of the nail splitting mechanism can be set arbitrarily.

7、Equipment with fault alarm, pressure monitoring and other alarm display function.

8, Chinese and English version of the two operating systems.

9、All core parts are imported from Italy, Sweden, Germany, Japan, the United States, Taiwan and other countries and regions.

10, the equipment can be optional “intelligent energy analysis and energy saving management system” and “intelligent equipment service big data cloud platform” and other functions.

11、Independent independent intellectual property rights

Automatic Pin Insertion Machine