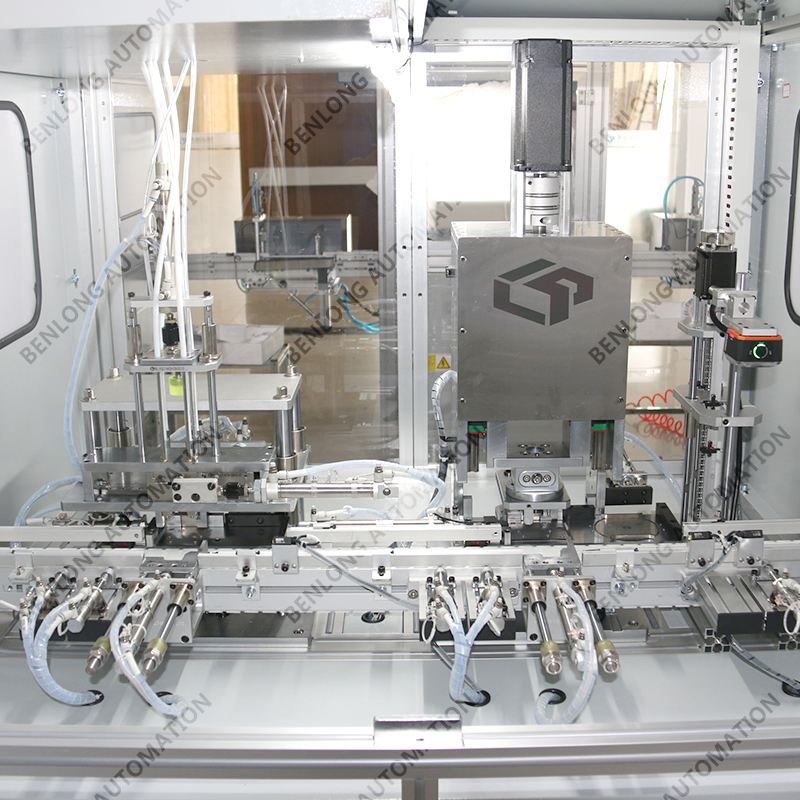

MCB Automatic Pin Insertion and Riveting Machine

See More>>Process Flow of MCB Automatic Riveting Machine

Ⅰ. Parts Feeding

· MCB housings, copper conductors, and contact pieces are automatically fed by vibratorybowl feeders or robotic arms.

· Workpieces are transferred to the workstation and clamped in precise positioning jigs.

Ⅱ. Rivet Feeding

· Rivets are oriented and sorted through a vibratory feeder.

· They are delivered to the riveting station via a feeding track or pipe.

Ⅲ. Rivet Insertion

· A pneumatic cylinder or servo-driven unit inserts the rivet into the reserved hole of theMCB housing and conductor assembly.

· The jig ensures accurate alignment during insertion.

Ⅳ. Riveting Forming

· The riveting head (pneumatic, hydraulic, or servo type) presses down to deform the rivettail, achieving a firm mechanical connection.

· Force and displacement sensors monitor the riveting process to ensure quality.

V. Quality Inspection

· Vision sensors or displacement detectors check for missing rivets, misalignment, orincomplete riveting.

· Defective parts are automatically rejected.

Ⅵ. Workpiece Transfer

· Finished MCB assemblies are conveyed to the next process station, such as sealing capassembly, trip mechanism installation, or functional testing.

MCB Automatic Pin Insertion and Riveting Machine