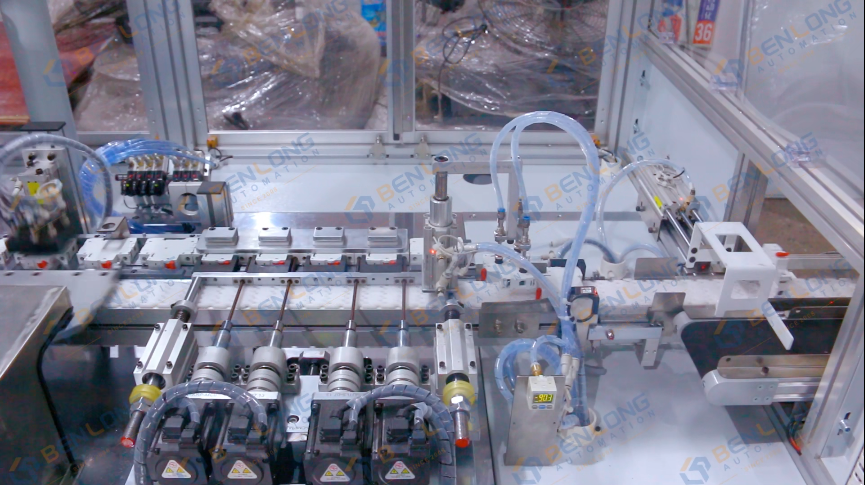

This state-of-the-art MCB Automatic Pin Insertion + Riveting + Inkjet Marking + Dual-side Terminal Screw Tightness Testing Equipment is designed for high-precision, high-efficiency manufacturing of miniature circuit breakers (MCBs). Combining advanced robotics, precision riveting, and automated quality control, it ensures consistent performance and reliability in every unit produced.

Key Features:

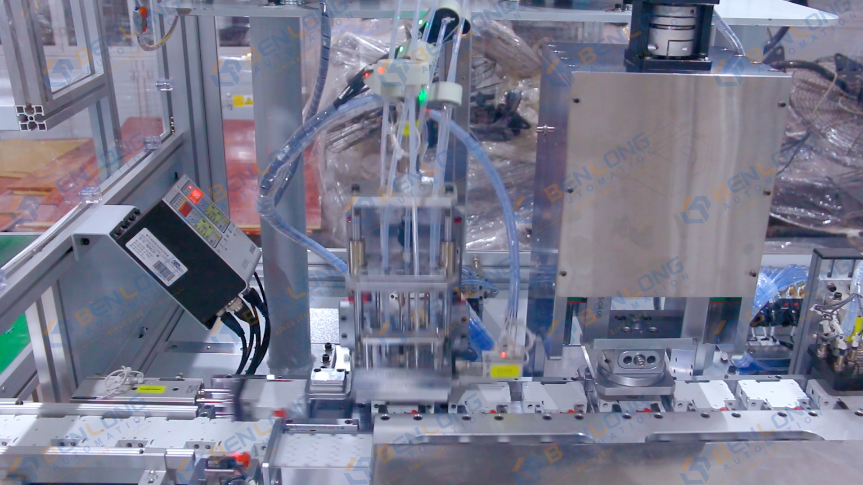

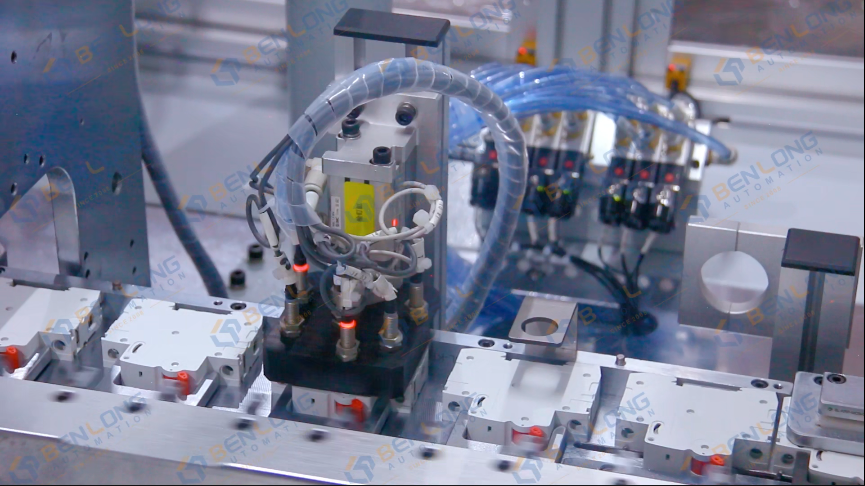

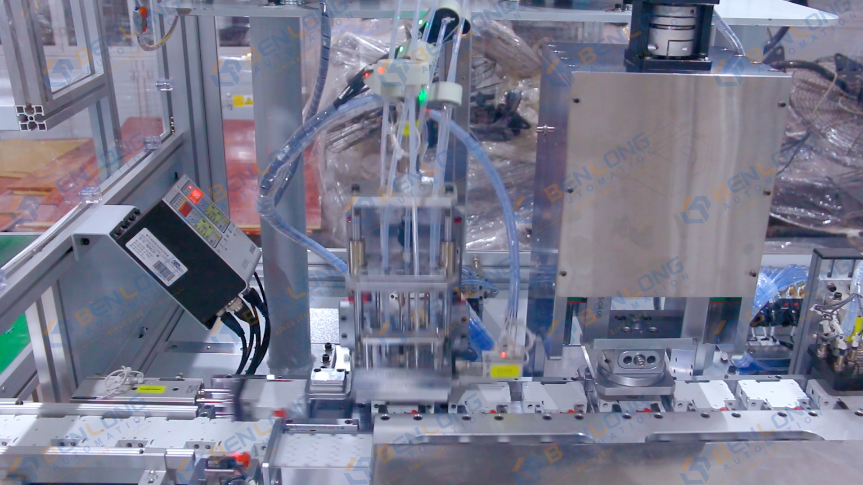

Automatic Pin Insertion: Precision-guided mechanism for error-free pin alignment and insertion, reducing manual intervention.

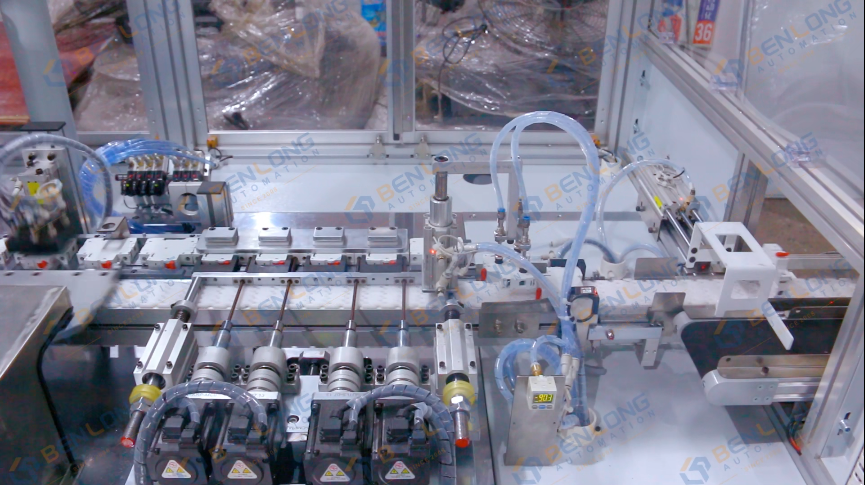

High-Speed Riveting: Robust riveting technology guarantees secure terminal connections with uniform pressure.

Inkjet/Laser Marking: Clear, permanent product labeling (model, ratings, QR codes) for traceability and compliance.

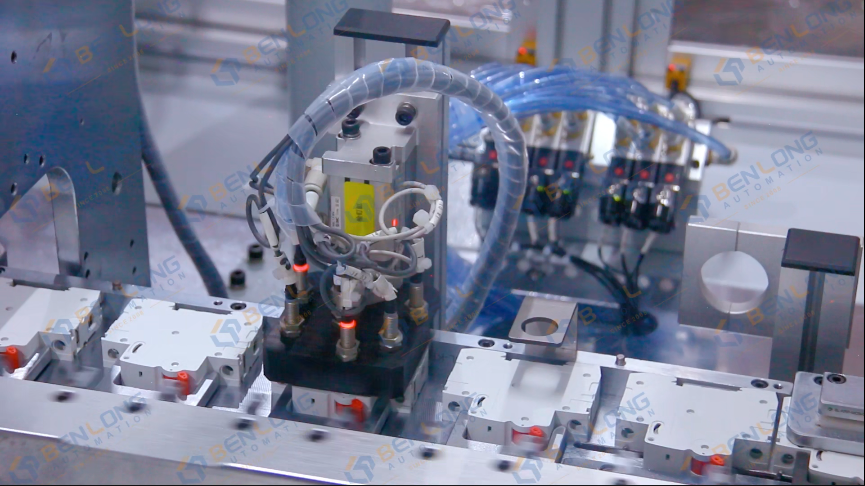

Dual-Side Screw Torque Verification: Automated testing of terminal screw tightness on both sides, preventing loose connections and ensuring electrical safety.

PLC-Controlled Operation: User-friendly interface with programmable logic for flexible production adjustments.

Benefits:

✔ 24/7 Production – Minimal downtime with automated material handling.

✔ Zero Defects – Integrated sensors detect and reject faulty components in real time.

✔ Scalable Output – Adaptable for low-to-high volume demands.

Ideal for MCB manufacturers seeking to enhance productivity, reduce labor costs, and maintain stringent IEC/UL standards. Customizable configurations available for specific assembly requirements.