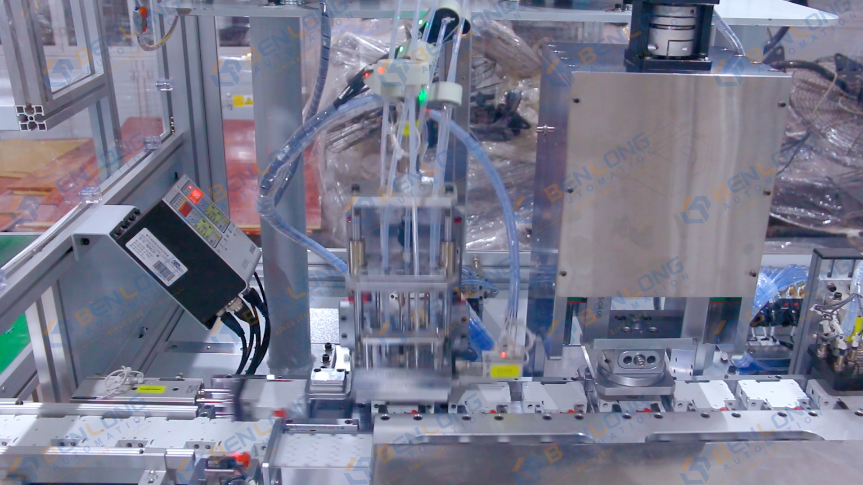

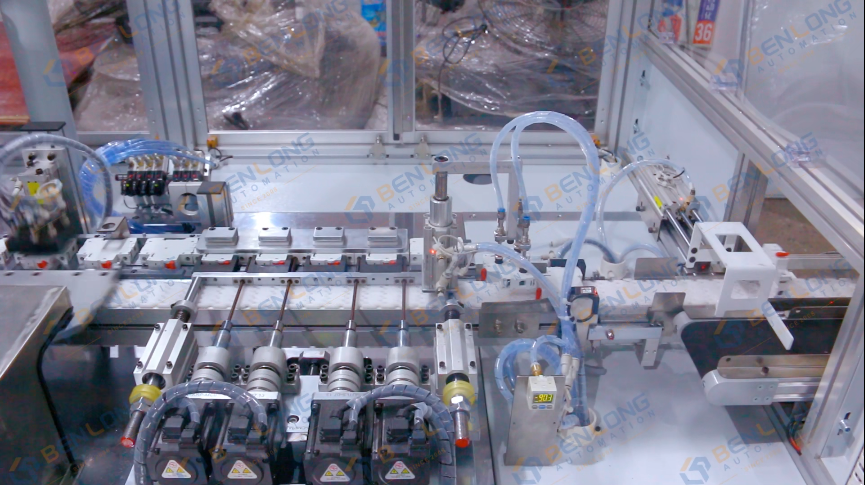

This equipment is specifically designed for the production of Miniature Circuit Breakers (MCBs), integrating three core functions: automatic pin insertion, riveting, and dual-side terminal screw torque testing, enabling high-precision, high-efficiency one-stop automated production.

Key Advantages:

Fully Automated Pin Insertion & Riveting: Utilizes high-precision servo drives and vision positioning systems to ensure zero deviation in pin placement, with consistent riveting strength. Compatible with multiple MCB models and allows quick changeovers.

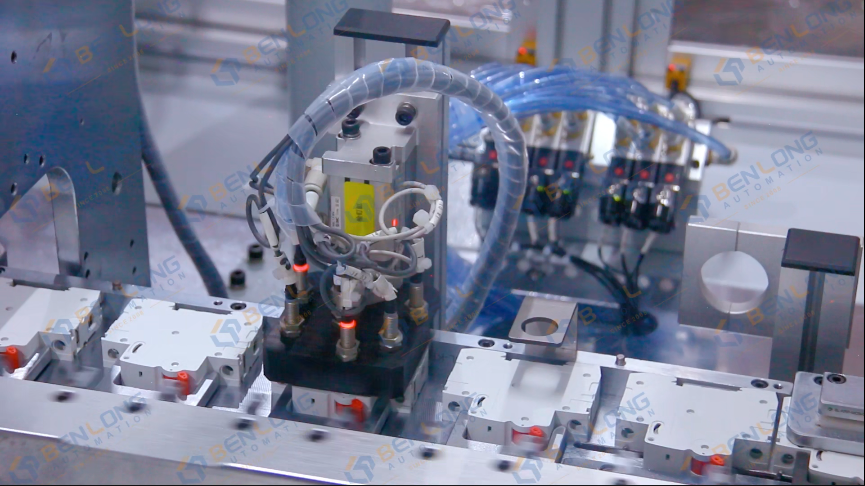

Intelligent Screw Torque Detection: Equipped with torque sensors and a closed-loop control system to monitor terminal screw tightening torque in real time, automatically flagging defective units to eliminate manual inspection errors.

High-Speed & Stable Production: Modular design combined with industrial-grade robotic arms achieves a cycle time of ≤3 seconds per unit, supporting 24/7 continuous operation with a defect rate below 0.1%.

Value Proposition:

Significantly reduces labor costs while increasing productivity by over 30%. Ensures 100% compliance with torque safety standards, making it a critical component of smart MCB production lines. Supports data traceability and seamless MES integration, empowering manufacturers to transition to Industry 4.0.

Applications: Automated assembly and testing of electrical components such as circuit breakers, contactors, and relays.

Post time: Jun-30-2025