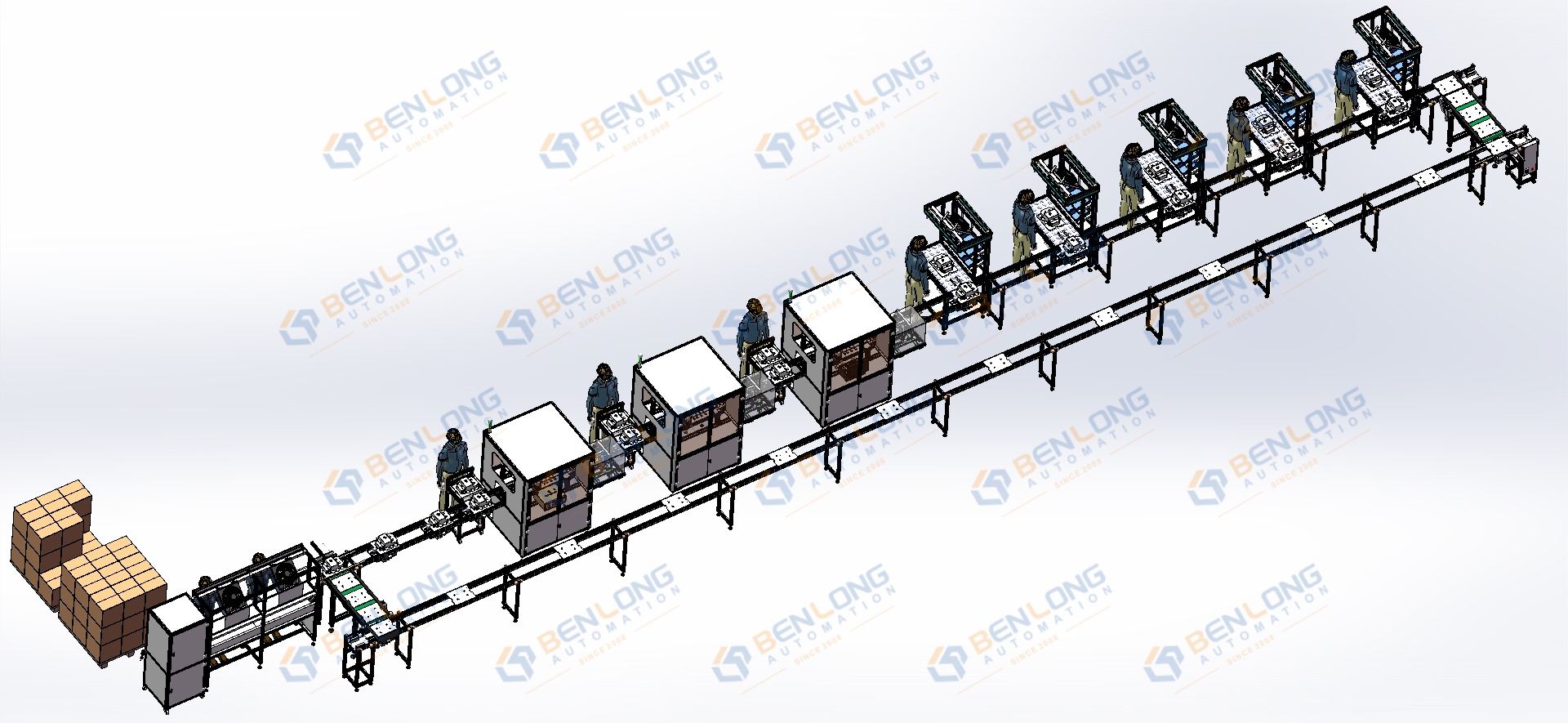

The Load Break Switch (LBS) automated production line is designed to achieve high efficiencyprecision, and reliability in the assembly and testing of medium and low voltage switching devices.At the initial stage, front-end manual assembly is performed to ensure the correct installation of keycomponents and to maintain flexibility for product variations. Once assembly is completed, eachproduct is placed onto a dedicated pallet, which serves as the carrier throughout the entireproduction process, The palletized products are then transferred smoothly along a double-speedchain conveyor system, which guarantees stable transportation and seamless integration withsubsequent automatic testing stations.

The line incorporates multiple automatic testing units to verify product quality and performance inaccordance with international standards. The first station performs circuit resistance testing,ensuring that contact resistance remains within the specified range to minimize energy loss andtemperature rise. This is followed by the on-off dielectric withstand test, which validates theinsulation strength of the switch under rated voltage and confirms safe isolation capability. Inaddition, a synchronization test is conducted to assess the mechanical and electrical coordination ofall poles, ensuring consistent operation and reliable performance in practical applications.

Through this structured process, the production line not only guarantees the accuracy andrepeatability of each test but also significantly improves overall productivity. By combining manualprecision at the front end with automated quality verification at the back end, the LBS productionline provides a comprehensive solution that enhances safety, efficiency, and consistency. This systemis ideally suited for large-scale manufacturing of high-quality load break switches, enablingmanufacturers to meet stringent market demands while ensuring product reliability and operationalsafety.

Post time: Aug-16-2025

20220919-1.jpg)