Production capacity: 15,000pcs/8hrs | Accuracy: ±0.01mm | Yield: ≥99.9

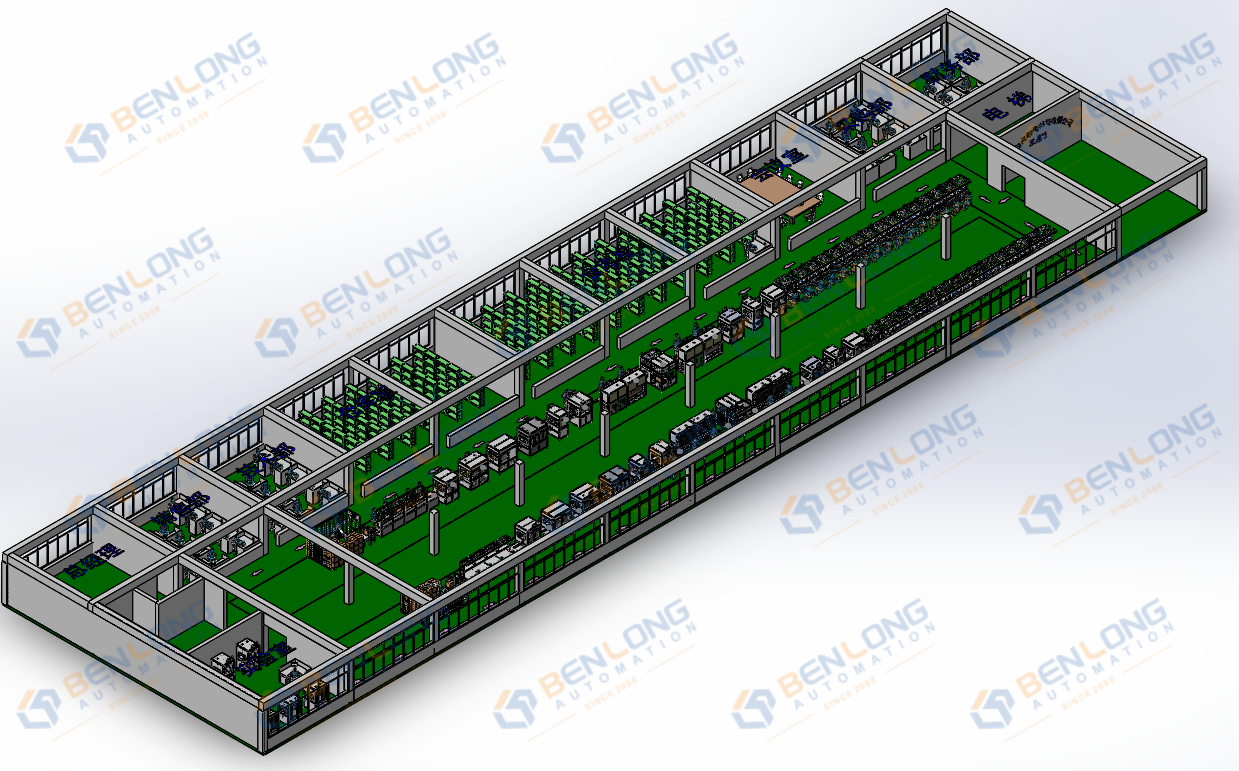

This production line adopts robot + AI vision + Industrial Internet of Things (IIoT) technology, designed for efficient mass production of intelligent MCBs, with the following core advantages:

Ultra-high-speed production: fully automatic loading, precision assembly and online inspection, with a beat of ≤2 seconds/unit, and a single-shift production capacity of up to 15,000 units, with an efficiency increase of 5 times compared with traditional production lines.

Zero-defect control: AI vision detects appearance defects, automated testing of decoupling characteristics, voltage insulation and communication functions (Wi-Fi/Bluetooth) to ensure 100% pass.

Flexible Manufacturing: Modular design supports 1P~4P model fast switching, parameters can be customized (6A~63A), changeover time <5 minutes.

Digitalized traceability: MES system binds unique ID, recording production data (torque, welding temperature, etc.) throughout the whole process, 15-year life cycle traceability.

Applicable fields: smart home, industrial power distribution, new energy system

Certification standards: IEC 60898, UL 489, GB/T 14048

Translated with DeepL.com (free version)

Post time: Jun-03-2025