1. Production Equipment (Assembly & Manufacturing)**

(1) Electronic Component Production Equipment**

- **SMT (Surface Mount Technology) Pick-and-Place Machine**: For automated PCB assembly (control boards, power modules).

- **Reflow Soldering Oven**: Cures solder joints on SMT-assembled PCBs.

- **Wave Soldering Machine** (if through-hole components are used): For DIP component soldering.

- **PCB Depaneling Machine**: Cuts connected PCB panels into individual boards.

- **Programmer/Burn-In Tool**: Flashes firmware onto the main control chip.

(2) Structural Component Processing Equipment**

- **Sheet Metal Processing Equipment** (for metal enclosures):

- Laser cutting machine, punch press, bending machine (for enclosure forming).

- Welding equipment (e.g., TIG welder).

- **Injection Molding Machine** (for plastic parts): Produces charging gun housings, panels, etc.

- **CNC Machine**: Precision machining for metal/plastic parts (e.g., heat sinks, connectors).

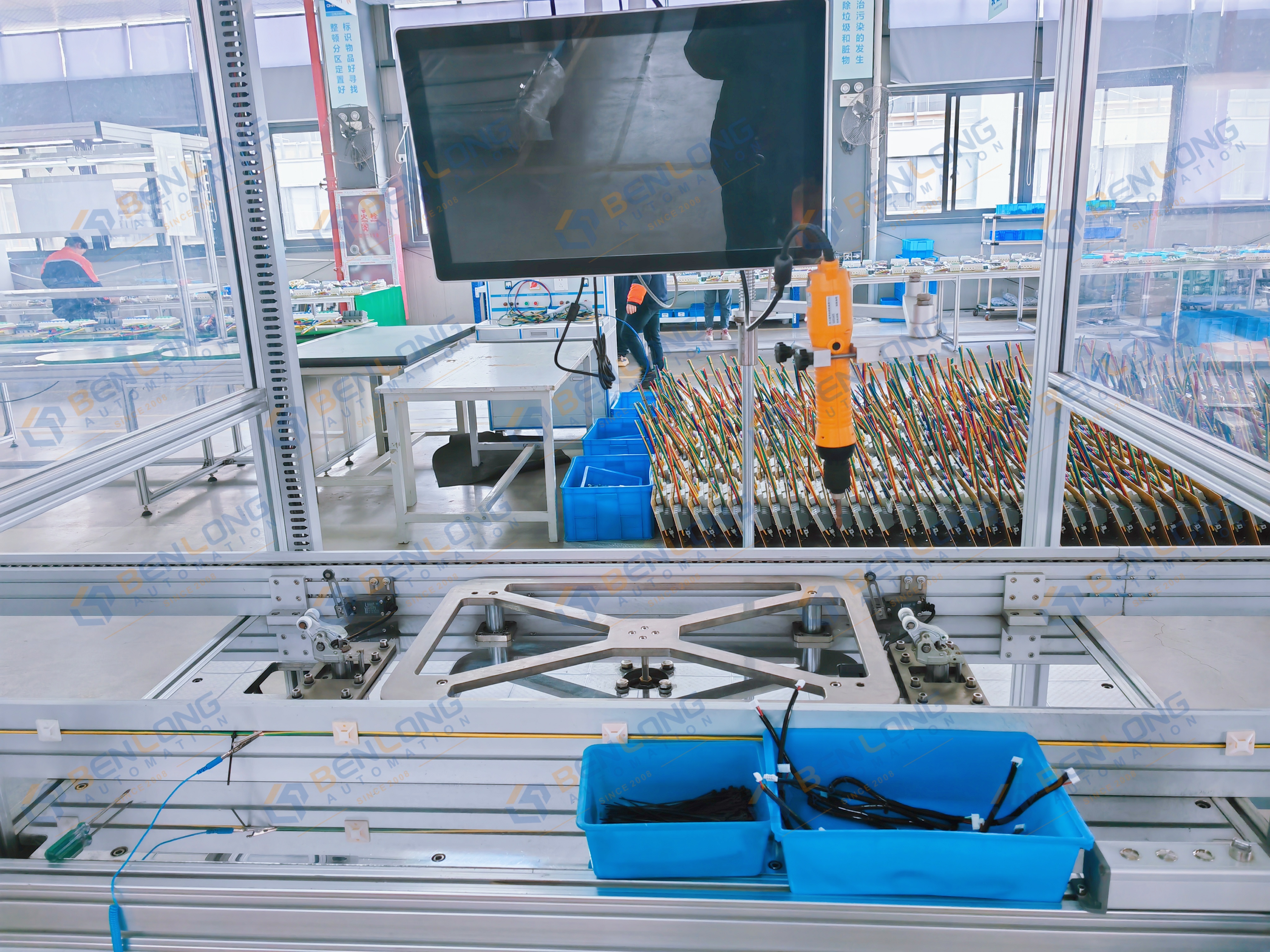

(3) Assembly Line Equipment**

- **Automated Conveyor Line**: Conveyor belts, robotic arms (for module assembly, screw fastening).

- **Crimping Machine**: For cable-to-terminal crimping (e.g., charging gun cables).

- **Automatic Screwdriving Machine**: Secures PCBs, enclosures, etc.

- **Sealant Dispensing Machine**: Applies waterproof sealant (e.g., for IP67-rated charging guns).

—

### **2. Testing Equipment (Quality Validation)**

#### **(1) Electrical Performance Testing**

- **Load Testing Cabinet**: Simulates full-power charging (e.g., 250kW load testing).

- **Hipot (High-Potential) Tester**: Checks insulation integrity (e.g., 2500V AC withstand test).

- **Ground Resistance Tester**: Ensures proper grounding.

- **Leakage Current Tester**: Detects electrical leakage.

#### **(2) Functional Testing**

- **Charging Protocol Tester**: Validates compatibility with CCS/CHAdeMO/GB/T standards.

- **Communication Test Equipment**: Tests 4G/5G/Wi-Fi/Bluetooth modules.

- **Payment System Tester**: Verifies RFID/NFC/QR code payment functionality.

#### **(3) Environmental Reliability Testing**

- **Thermal Chamber**: Temperature cycling tests (-30°C to 70°C).

- **Salt Spray Test Chamber**: 48-hour corrosion resistance testing (for coastal areas).

- **Vibration Test Bench**: Simulates transportation/usage vibrations.

—

### **3. Auxiliary Equipment**

- **ESD (Electrostatic Discharge) Protection**: Anti-static wrist straps, ionizers (to protect sensitive components).

- **Burn-In Test Room**: Extended operational testing (e.g., 72-hour continuous run).

- **Packaging Equipment**: Automatic box sealers, label printers (for barcodes/product labels).

- **Logistics Equipment**: Forklifts, heavy-duty shelving (for large charging piles weighing 500kg+).

—

### **Key Equipment Examples (by Charger Type)**

| **Equipment Type** | **AC Charger (7kW–22kW)** | **DC Fast Charger (60kW–350kW)** |

|————————–|——————————–|—————————————-|

| **Core Production** | SMT machine, injection molder | High-power module assembly line, liquid cooling test rig |

| **Testing Focus** | Leakage current, communication | Load cycling, thermal performance |

| **Special Requirements** | Basic assembly line | High-voltage test equipment (e.g., 1000V DC hipot) |

—

### **Notes**

1. **Equipment Selection**: DC fast chargers require higher-capacity test gear (e.g., 1500V testers).

2. **Automation Level**: Mass production lines benefit from robotics/AGVs.

3. **Safety Compliance**: Equipment must meet UL/CE/GB standards.

Post time: Jun-28-2025