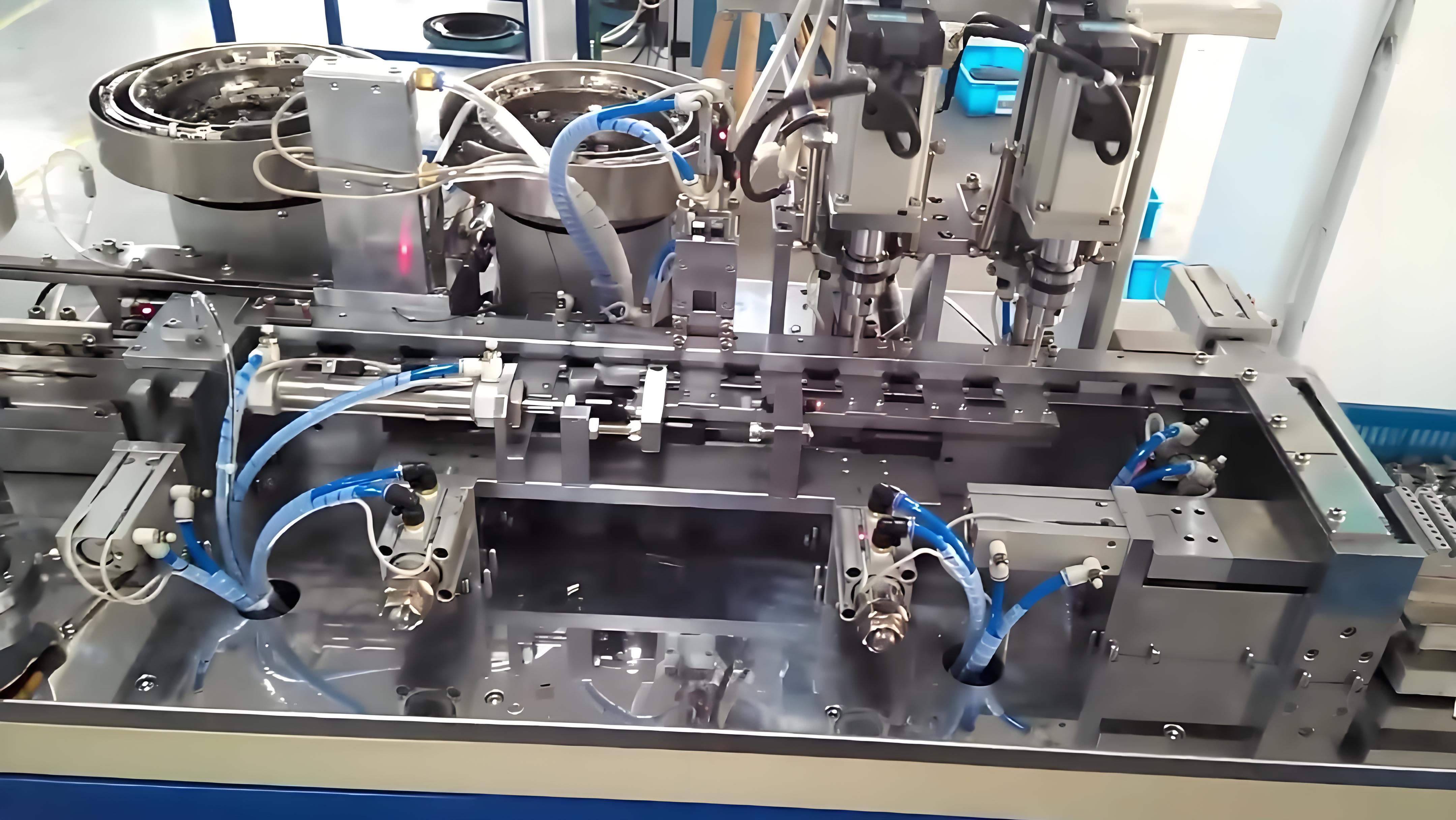

Terminal Clamp automatic assembly machine

See More>>Process Flow

1. Feeding and Loading Materials

• Components such as plastic shells, conductive parts, springs, and wire-pressing parts are automatically fed through vibrating trays or material hoppers and arranged in sequence.

2. Part Positioning and Conveying

• Each component is conveyed to the assembly station and positioned by fixtures to ensure installation accuracy.

3. Conductive Part Installation

• The machine automatically inserts the copper conductive parts into the corresponding positions of the plastic shell and presses them firmly in place.

4. Spring Clip Installation

• Spring clips (or wire-pressing springs) are automatically fed into the spring clip structure and installed in the plastic shell to achieve the wire-pressing function.

5. Secondary Part Assembly

• Screws, wire-pressing plates, or other auxiliary components are assembled to complete the terminal functional structure.

6. Inspection and Correction

• Online inspection is conducted to check if the conductive parts, springs, etc. are in place, and defective products are automatically removed.

7. Finished Product Discharge

• Qualified terminals are collected by an automatic discharge device for subsequent packaging.

Terminal Clamp Automatic assembly machine